| Variant | Art.-No. 507570 | fischer Bolt Anchor FBN II 16/50 R stainless steel | ||

| ETA-approval | ||||

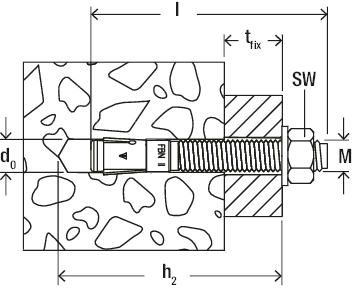

| Drill diameter | 16 | [mm] | ||

| Min. drill hole depth for through fixings | 154 | [mm] | ||

| Anchor length | 168 | [mm] | ||

| Max. usable length hef-max./hef-min. | 50/65 | [mm] | ||

| Thread | M16x105 | [mm] | ||

| Width across nut | 24 | [mm] | ||

| Packaging | Folding-box | |||

| Quantity/pack | 10 | [St.] | ||

| GTIN (EAN-Code) | 4048962087574 | |||

| Price / Pack | 8496.00 ₹ | |||

Product Description

Application and Permission

Approved for:

Also suitable for:

* You can find detailed information on building materials in the registration document.

Permission

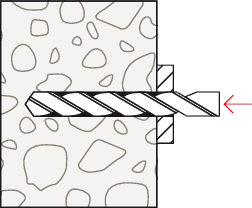

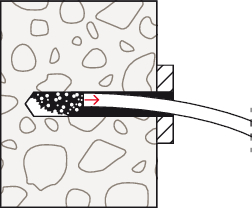

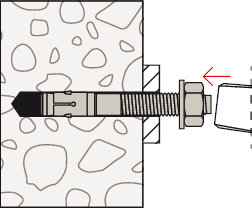

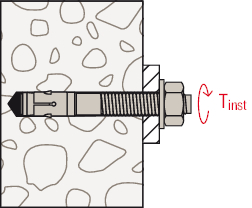

Assembly Instruction

Technical Data

Technical Data

| ETA-approval | |||

| Drill diameter | 16 | [mm] | |

| Min. drill hole depth for through fixings | 154 | [mm] | |

| Anchor length | 168 | [mm] | |

| Max. usable length hef-max./hef-min. | 50/65 | [mm] | |

| Thread | M16x105 | [mm] | |

| Width across nut | 24 | [mm] | |

| Packaging | Folding-box | ||

| Quantity/pack | 10 | [St.] | |

| GTIN (EAN-Code) | 4048962087574 |

Documents for Downloading

Additional Documents

Approvals

| Title | Type | Created | Valid Till |

|---|---|---|---|

| Title ETA - European Technical Assessment (PDF, 2 MB) European Technical Assessment for fischer Bolt Anchor FBN II, FBN II A4 | Type ETA-07/0211 | Created 19-05-2016 | Valid Till |

| Title DOP - Declaration of Performance (PDF, 1 MB) | Type DoP 0192 | Created 27-07-2020 | Valid Till |

| Title DOP - Declaration of Performance (PDF, 1 MB) Declaration of Performance fischer Bolt Anchor FBN II - FBN II A4, according European Technical Assessment ETA-07/0211 | Type DoP No. 0015 | Created 25-05-2016 | Valid Till |